Track Monitoring Systems

Track monitoring systems can provide timely warning of developing geotechnical issues that could affect track geometry and safety. Datasheet

Track Monitoring Solutions

Track monitoring systems offer continuous operation and automated processing, alerts, data visualization, and reports.

GEO implements most track monitoring solutions with AMTS systems, but other sensors include shape arrays, dynamic deflection sensors, and tiltmeters.

Advantages of Automation

- Automation eliminates most site visits, reducing costs and enhancing safety.

- Automation obtains frequent measurements, increasing confidence in the data and providing early identification of unwanted trends.

- Automation operates continuously, updating a secure website and sending alerts as needed.

Track Monitoring with AMTS

Components include rail-clip prisms, an AMTS system, and GeoCloud data processing and presentation.

Rail clip prisms are installed in arrays, typically at the same interval along both rails to form prism pairs. Other prisms may be installed to monitor the sub-ballast or engineered soil beneath the tracks.

The AMTS system monitors the spatial position of the prisms and reports changes from baseline measurements recorded when the system was installed.

The AMTS must be positioned with good sight-lines to the prisms. Location flexibility is provided by solar power and GEO’s AMTS towers. Multiple AMTS systems can be optically networked to monitor very long spans of track.

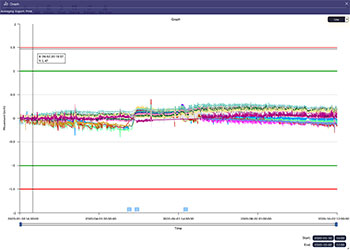

AMTS measurements are relayed to GeoCloud web servers by cellular modem. The servers apply least-squares adjustments to the AMTS measurements, process the data as required, send alerts of any alarm conditions, and then present the data on a secure website.

The GeoCloud website typically shows vertical displacements (settlement or heave). Advanced processing may include presentation of profiles, alinements, cross levels, and warp.

This AMTS system is monitoring rail clip prisms on the tracks and road prisms on a road crossing.

AMTS systems mounted on towers can be positioned nearly anywhere. Solar panels provide power.

Rail clip prisms are clamped to the rail and then aligned to the AMTS.

This low-profile prism was installed to monitor deformation in the sub-ballast.

The arrays of rail clip prisms are typically installed along both rails.

Data can be presented in plan views, trend plots, and tabular form.

Track Monitoring with Shape Arrays

Shape arrays are inclinometer-like instruments that provide measurements for profiles of settlement or heave along the axis of the track.

System components include the shape array, protective conduit, a wireless logger, and an internet gateway. The shape array is inserted into the protective conduit and installed parallel to the rails.

When one end of the array is established as the point of fixity, measurements can be processed to show the track profile.

Shape arrays are connected to a wireless logger which transmits data to a GeoCloud server via a cellular internet gateway. The secure GeoCloud website displays plots and can send out alerts if deviations exceed preset limits.

Track Monitoring - Dynamic Deflection Sensor

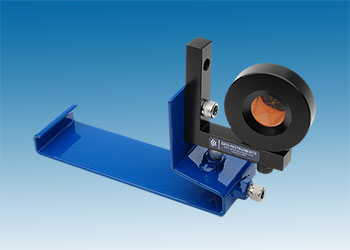

The FLX-Rail dynamic deflection sensor can record the maximum vertical deflection of a rail under the load of a passing train.

The FLX-Rail sensor uses an internal optical sensor to monitor the distance between a rail plate, which is magnetically clamped to the foot of the rail, and a reference plate, which contacts the ballast.

The sensor stays in a low-power standby mode until it detects vibrations from an approaching train. It then becomes active, continuously sampling the optical sensor at 350Hz. After the train has passed by, the sensor stores the maximum measured deflection and transmits the measurement to a GeoCloud website, and returns to standby mode.

Track Monitoring - Tiltmeters

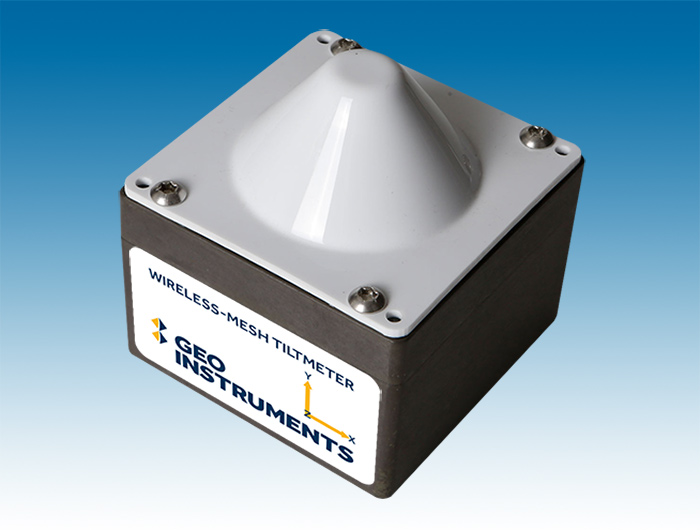

Tiltmeters can be used to monitor rotation of track ties.

System components include wireless tiltmeters and an internet gateway. The tiltmeters are installed on ties, with one axis parallel to the ties and the other axis parallel to the rails.

Tiltmeter measurements can confirm stability or warn of movements and indicate relative changes in crosslevel. Rigid elements between tiltmeters and a point of fixity are required for other calculations.

Wireless tiltmeters send measurements to a GeoCloud server via a cellular gateway. A secure GeoCloud website displays plots and can send out alerts if movement thresholds are exceeded.