MPBX Borehole Extensometers

MPBX (Multi-Point Borehole Extensometers) are used to monitor for potential settlement and heave induced by construction activities such as tunneling and excavation. They can also be used to monitor deformation of retaining walls, cut slopes, and underground openings. Standard MPBX and Digital MPBX

MPBX Applications

MPBX (also called rod extensometers) monitor changes in distances between downhole anchors and a reference head. Typical applications include:

- Monitoring settlement in soil above tunneling and other mining activity.

- Monitoring settlement due to loading of foundation soils.

- Monitoring deformation of retaining walls, cut slopes, and tunnel walls.

MPBX Components

MPBX components include anchors, rods, and a reference head with displacement sensors. Components are typically delivered pre-assembled and coiled, ready to install.

Anchors and rods are installed at specified depths in the borehole. Rods run upwards from the anchors to the reference head at the borehole collar.

After the downhole components are installed, the borehole is backfilled with grout and the reference head is fixed at the borehole collar.

MPBX Operation

Sensors inside the reference head monitor displacement of the rods, which follow the upward or downward movement of the anchors.

Measurements can be referenced to the borehole collar at the top or to the deepest anchor at the bottom.

Many applications require a datalogger and wireless data transmissions to the internet. This is especially important when the MPBX is located in a location that is difficult to access safely or requires traffic control.

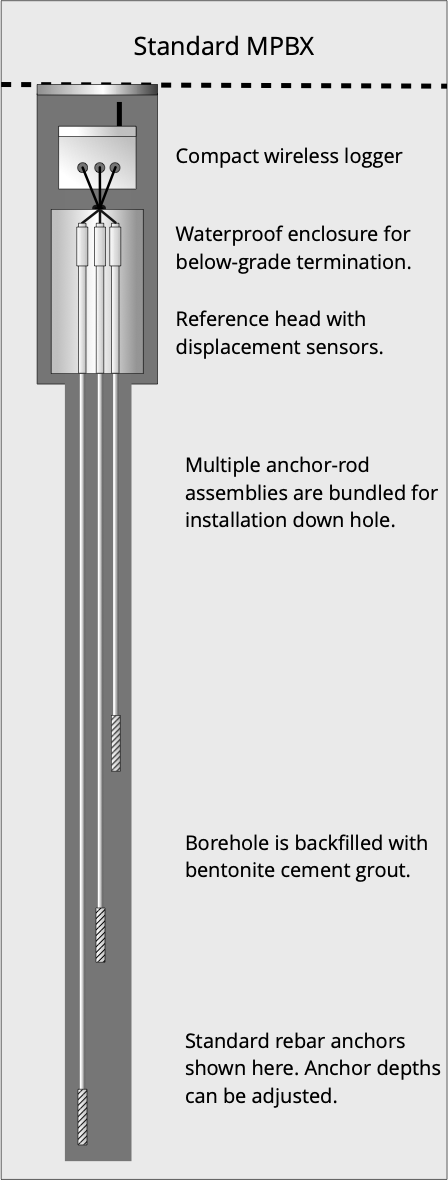

Standard MPBX

- Anchor-rod assemblies are separate, one for each monitored point.

- Bundled anchor-rods require a larger diameter borehole.

- Below-grade termination requires a waterproof enclosure for reference head.

- Anchor depths are set during manufacturing, but can be adjusted.

- Standard rebar anchors and geotextile packer anchors are available.

- Some configurations support manual verification readings.

- Compact wireless dataloggers are available.

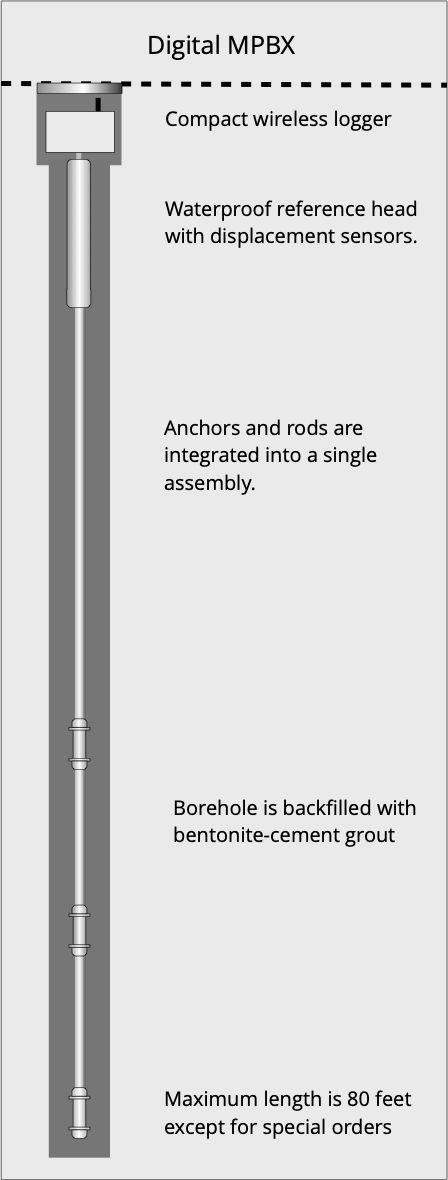

Digital MPBX

- Anchor and rods are integrated into a single assembly.

- Single assembly can be installed in smaller diameter boreholes.

- Sensors are enclosed in waterproof reference head.

- Anchor depths are set during manufacturing and cannot be adjusted.

- Versions are available for rock or soil applications.

- Compact wireless dataloggers are available.

Standard MPBX

This standard MPBX was supplied with geotextile packer anchors. The anchors were later inflated with grout.

This is a flush installation, so the reference head and sensors were packed into a waterproof enclosure.

A LidLink antenna was added so that the logger can transmit data to a nearby cell tower.

Digital MPBX

Upper photo shows the small diameter Digital MPBX head which contains six sensors and is waterproof. Lower photo shows an anchor.

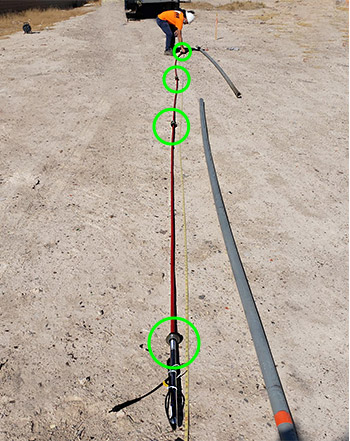

Checking anchor depths before installation. All pre-assembled MPBX must have anchor depths specified at time of manufacturing.

All MPBXs must be lifted to avoid bending the rods during installation. The single assembly of rods and anchors makes installation easier.