AMTS (Automated Motorized Total Stations) transmit high-precision total station measurements from project sites to GeoCloud project websites. They provide automated optical monitoring of displacements, deformation, and settlements. Datasheet

Optical Monitoring

Optical monitoring requires survey prisms, total stations, and processing.

The survey prisms are fixed to critical points on the structure, and the total station is used to record angles and distances to each prism. The measurements are offloaded to software that applies statistically-weighted adjustments and outputs coordinates for each prism.

Successive measurements are obtained at regular intervals and processed the same way. Changes in coordinates indicate that movement has occurred. The magnitude and direction of the movement are found by comparing current and initial coordinates.

AMTS monitoring systems automate these steps to deliver alerts, plots and reports via a project website.

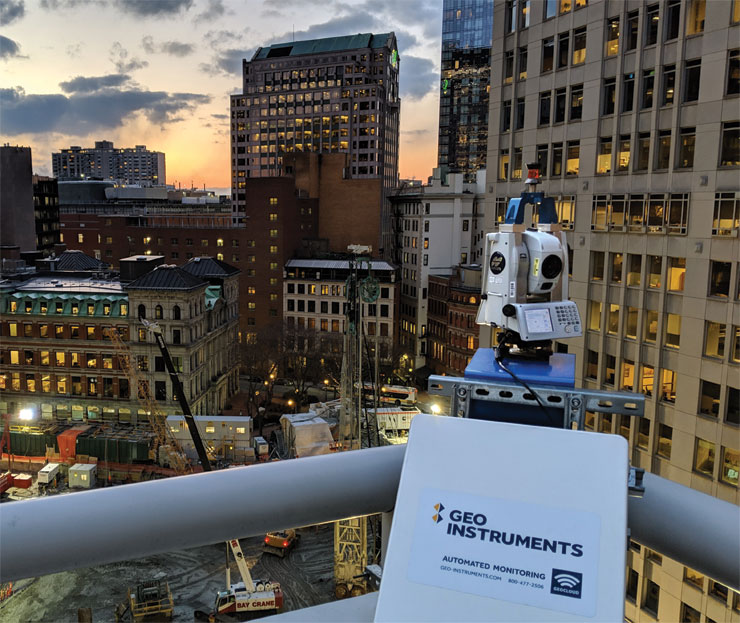

AMTS at a project site in Boston

AMTS System Components

AMTS systems are designed to provide continuous, unattended monitoring. Components of the system include:

Survey Prisms installed at monitoring points and control points.

AMTS systems consisting of a high-precision robotic total station managed by a controller. Multiple AMTS systems are deployed at some sites.

Controllers that schedule and direct AMTS measurements and then transmit the recorded data to the internet.

GeoCloud Server that performs quality checks, processes the measurements with MonStar least-squares software, and formats data for a website database.

GeoCloud Web Site that provides alarms, site views, graphs, and integration with standard geotechnical instrumentation.

This tower-mounted AMTS is monitoring rail-clip prisms.

Deploying AMTS

Careful placement of the AMTS and the prisms is important for creating strong geometric networks.

The AMTS must be positioned for clear lines-of-sight to monitoring points and control points. GEO's specialized mounting brackets and towers were developed for this purpose.

Prisms are installed at specified locations on the structure. These monitoring points provide settlement and displacement data. GEO deploys specialized survey prisms for different types of structures.

Prisms are also installed at locations outside the zone of influence. These control points provide data to establish the exact position of the AMTS at each measurement cycle. GEO installs redundant control points to enhance precision and to provide the flexibility to relocate the AMTS as needed.

The AMTS observes both monitoring points and control points at each measurement cycle. GEO programs the AMTS to record three pairs of observations for each prism to ensure that a complete and accurate set of measurements is obtained for each cycle.

Related Pages

AMTS Advantages

Automated: Automation provides continuous monitoring and rapid processing of measurements, allowing early identification of any unwanted displacements.

Accurate: Multiple observations from a fixed location and least-squares processing delivers accuracies similar to first-order surveys.

Cost-effective: AMTS systems provide wide-area coverage at a low-cost per monitored point. Unattended operation and automated processing also lower costs and save time.

Compatible: GEO’s MonStar software can output data as specified by the customer, suitable to combine with other geotechnical instrumentation or for use with CAD-generated plan views and as-builts.

AMTS configuration involves recording the initial location of all the prisms.

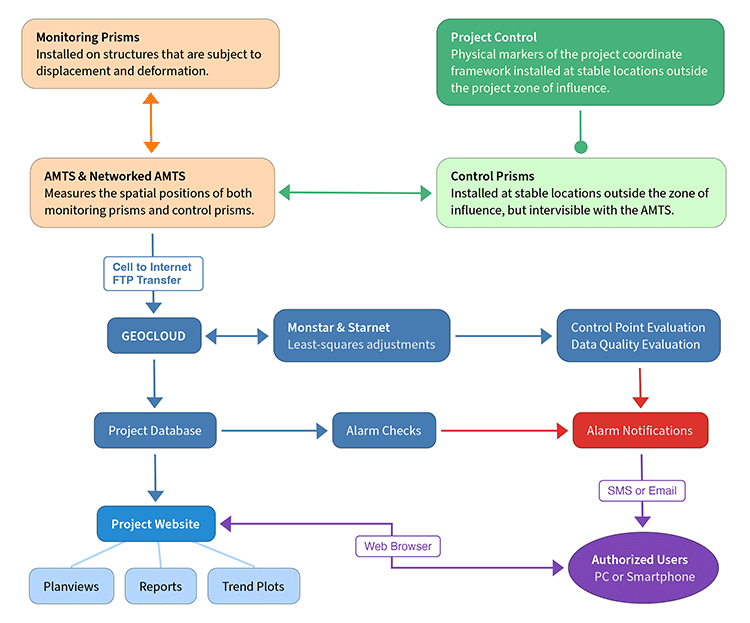

AMTS to GeoCloud Data Flow

Each AMTS measurement cycle consists of multiple observations of all prisms. Measurements are then transmitted to GeoCloud servers.

GeoCloud directs measurements to Monstar for least-squares adjustments and quality checks. Monstar formats the data for import into the GeoCloud project database.

The import process checks for missing data, tests measurements against alarm thresholds, and then stores data in the project database. Alarms are sent out by email or text message.

At this point, AMTS measurements are fully integrated with data from other sensor types and available for the plots, planviews, and reports generated by the GeoCloud project website.

Example Installations

Track Monitoring

Highway Work

Bridge Repair

Stack Demolition

Structures and Excavation

Seawall Repairs

Metro Tunnel

Renovation of Structures

Structures near Tunnel