Ballston Pedestrian Bridge

The Project

The redevelopment plan for Ballston Quarter, the commercial center of Arlington, Virginia, included a new pedestrian bridge, shown in a conceptual drawing above.

The new bridge superstructure was fabricated off site, then transported to the location as shown above, and finally lifted onto prepared piers, as shown in the next photo.

The superstructure weighs 100 tons and provides 157 feet of walkway, varying between 12 and 19 feet wide. The transport and installation occurred over a single weekend.

Monitoring Requirements

Although standard survey instruments were proposed for placement activity, engineers wanted assurance that structural integrity of the superstructure would be maintained during transport and lifting. GEO-Instruments was asked to provide near-real time monitoring of stresses and possible deformation.

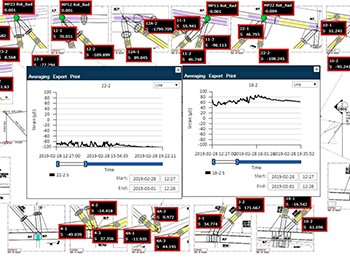

To monitor stresses, GEO installed 56 vibrating wire strain gauges at specified locations. The gauges provided strain readings at intervals of 1 Hz. GEO selected compact, spot-weldable gauges to minimize welding effects on the structural steel and used Campbell Scientific CDM modules to achieve the 1 hz reading intervals.

To monitor changes in structural geometry, GEO installed string potentiometers. These measured distances between specified structural elements. Measurements were recorded at 3-second intervals. Loggers, in the blue boxes in the background, were in operation during transport of the super structure.

All of the sensors were connected to battery-powered, wireless loggers that were capable of maintaining a rapid throughput. The loggers transmitted measurements via cellular modems to GeoCloud servers that checked for alarm conditions. GeoCloud Quickview provided graphical presentation of data that engineers could view with PCs and smartphones.

Results

GEO supplied, configured, installed, and commissioned the monitoring system within a short 36-hour window. The instrumentation program helped engineers manage risk while they transported and successfully placed the bridge superstructure. Strain and deformation values remained below alarm thresholds during the entire operation, including the week afterwards.