The Locator One GNSS sensor provides automated monitoring of settlement and lateral displacements. Datasheet

Locator One GNSS Sensor

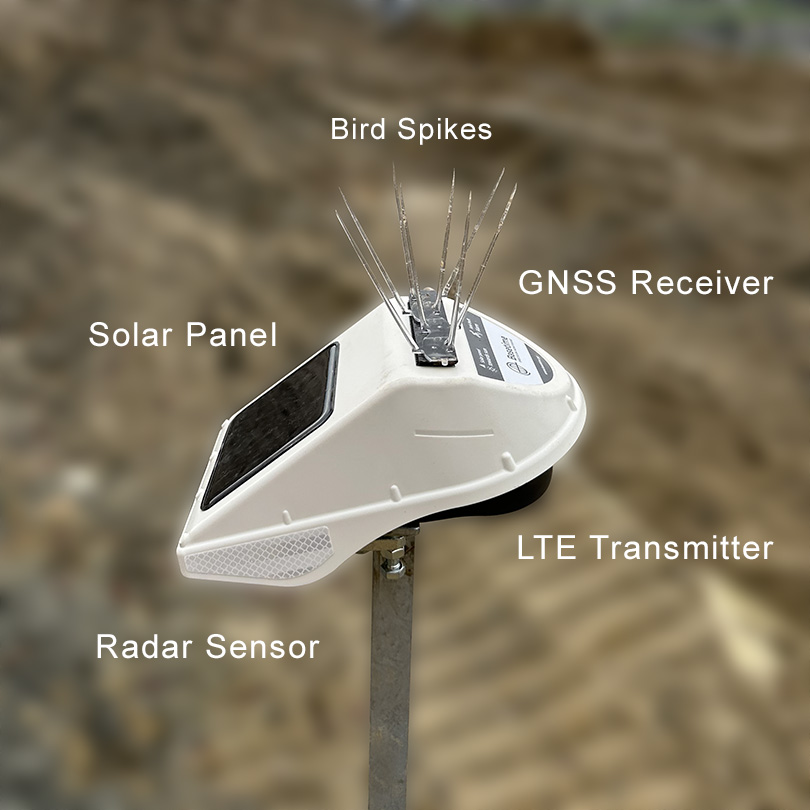

The Locator One is a compact, self-powered sensor that combines a GNSS receiver, ground-facing radar, and cloud connectivity. It autonomously acquires and transmits geodetic data to the Cloud.

The cloud server processes the data, applies adjustments, and outputs absolute coordinates. Changes from baseline coordinates reveal the magnitude and direction of displacements.

A GeoCloud project website presents the data visually in map views and graphs and sends out alerts if alarm thresholds are exceeded.

Locator One Applications

- Automating measurements of settlement plates.

- Monitoring horizontal displacement of earth retention structures such as MSE walls or sheet pile walls.

- Monitoring slope stability at open pit mines, tailings dams, and highway cuts.

- Monitoring displacement and settlement of buildings and utilities near excavation and tunneling projects.

Locator One GNSS sensor monitoring settlement plate.

Locator One GNSS sensor clamped to sheet pile.

Locator One GNSS sensor monitoring slope stability.

Locator One monitoring structural displacements.

Locator One Advantages

- High-precision 3D Measurements.

- No line-of sight issues and no problems with fog, rain, or snow.

- Simple to install, simple to use, and very little maintenance required.

- Very little equipment needed on site.

Locator One Specifications

Observation Technique: Fast-static, with 186 channels available for recording observations at 1Hz for 5 minutes. Default observation time can be modified as needed.

Maximum Baseline: 4 km. Baseline is the distance between sensor at a reference point and sensors at monitoring points.

Satellite Constellations: Compatible with GPS, GLOSNASS, Galileo, QZSS, and BeiDou satellites.

Post Processed Precision:

±2mm horizontal, ±4 mm vertical.

Measurements per Day: 6 per day is standard. Up to 24 per day is possible at ideal locations.

Weather Rating: IP 65 for water ingress, -4 to 140 °F for temperature.

Power: Supercapacitor charged by built-in solar panel. Fully charged supercapacitor can provide 8 months of power without solar.

Ground-Facing Radar: Millimeter precision when used with base plate as target. Has 13 foot range.

Locator One GNSS Sensors are designed and manufactured in The Netherlands by Basetime BV. Geo-Instruments is the U.S. distributor for Basetime.

Installation Requirements

Cellular Connection: LTE-M cellular connectivity is required and is widely available. Each sensor connects independently via its built-in universal SIM.

Monitoring Points: One sensor is installed at each monitoring point. There is no practical limit for the number of monitoring points.

Reference Point: One sensor should be installed at a stable location outside the zone of influence. It is used to correct for atmospheric conditions that might affect satellite signals.

Clear Horizon: Ideal locations for sensors have a clear horizon with no obstacles above an elevation of 10°. This is particularly important for the reference point.

Mounting Hardware

Bottom of sensor has two built-in clamps for a mounting plate.

Mounting Plate for Pipe: Connects sensor to 1-inch diameter pipe. Bell adaptor used to fit 2-inch diameter riser pipe.

Mounting Plate with Clamp: Clamps sensor to vertical elements such as a sheet pile.

Base Plate for Structures: Used to mount sensor on structure. Has holes for mounting bolts and threaded fitting for 1-inch standoff pipe.

Standoff Pipe for Structures: Elevates sensor for better view of the sky. 1-inch diameter pipe, threaded at one or both ends. Supplied to required length or sourced locally.

Settlement Plates: Standard settlement plate components. Includes threaded mounting plate above. See Settlement plates

Request a Quote

Help Notes for Quote Request

Number of Sensors

Enter the number of monitoring points + 1 reference point.

Coordinate System

Relative to installed location provides precise measurements that are not tied to the project grid. No survey or geodetic knowledge is required.

Aligned to project grid provides measurements that are tied to the project grid. This requires knowledge of the coordinate system in use and the location of the reference point within that coordinate system.

Installation Services

Choose Required if you want GEO to install and configure the sensors. Choose Not Required if you will install by yourself.

About Contact Information

Click the contact information tab to enter your contact information and submit the form. The contact information is needed to generate a quote. In most cases, we'll also need to talk to you to learn some details of your project and the kind of mounting hardware you will need.