Excessive vibration from construction activities can damage adjacent buildings and sensitive equipment. Monitoring helps construction teams maintain safe, non-damaging vibration levels. Datasheet

Why Monitor Construction Vibrations?

-

Risk Management

Excessive vibrations can lead to property damage, litigation, project delays, and increased costs.

-

Construction Control

Monitoring helps construction teams adjust their operations to avoid exceeding safe limits.

-

Compliance and Community Relations

Monitoring provides documentation to satisfy regulatory agencies and also helps builders manage relations with neighboring property owners, reducing complaints and project delays.

-

Legal Defense

Monitoring provides a record of vibrations from the site that can help resolve damage claims.

Vibrations from demolition and excavation can damage adjacent buildings and underground infrastructure.

What Activities Generate the Most Vibration?

Early Phase Activities

Construction activities that generate the most vibration include:

- Clearing of the site, including demolition and removal of rubble.

- Compaction and leveling of foundation soils.

- Construction of deep foundations, including excavation, pile driving, and drilling.

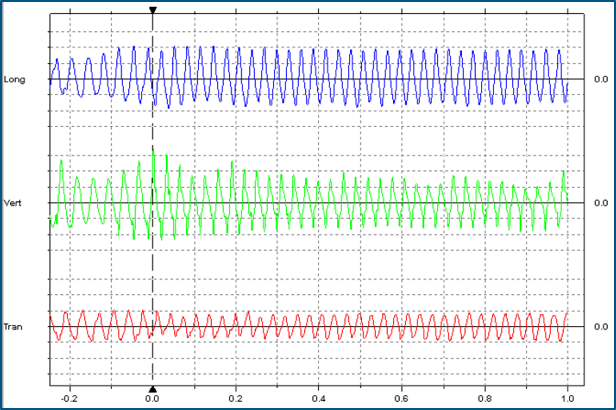

Continuous Vibrations

Continuous vibrations are more likely to be damaging: vibratory compaction, vibratory pile driving, excavation equipment, pavement rubblizing

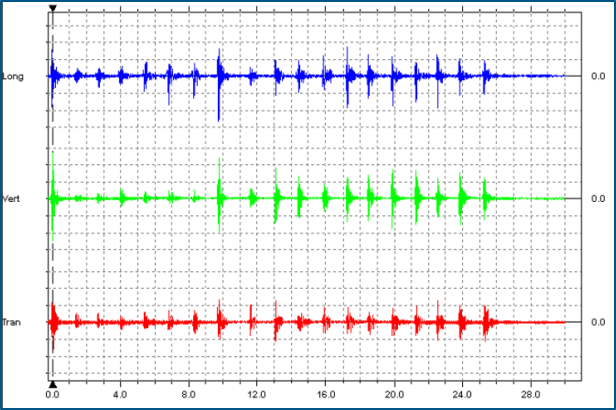

Transient Vibrations

Transient vibrations are typically less damaging: blasting, impact pile driving, dynamic compaction.

What Vibration Levels Cause Damage?

The Potential for Damage

Factors affecting the potential for damage include:

Type of structure: Modern steel and concrete structures are less susceptible to damage than wood-framed and masonry structures.

Age of structure: Historical buildings or buildings that have experienced damaging events are more susceptible to vibration damage.

Function of structure: Some structures are used for vibration-sensitive activities and have vibration sensitive equipment.

Proximity of source: Ground vibrations attenuate with distance from the source of vibration.

Soil: Some soils, such as clays, transmit vibrations more efficiently than other types of soil.

Duration of vibrations: Continuous vibrations generally have more damage potential because they increase the chance of resonant amplification.

Frequency and velocity: Higher velocities and lower frequencies of particle motion are both more damaging.

Vibration Limits

Vibration standards provide guidance in setting safe vibration limits.

Standards & Vibration Limits

A paper by Mark Svinkin, available for free download from the ISSMGE online library, reviews a number of standards and vibration limits, including the widely referenced RI 8507 report.

It concludes that vibration impacts on structures are best monitored on the structures themselves; that ground vibrations should be measured for possible dynamic settlement; and suggests some generic limits.

FTA Manual

The FTA manual provides procedures for assessing the impact of noise and vibration from transit construction projects. More than half of the manual addresses noise and human factors. The vibration sections discuss project equipment, structure type, event frequency, and vibration limits.

Local Building codes

Local building codes are the primary guidance for most builders. Many of the codes are localized versions of the RI 8507 | OSMRE report.

Specialized Standards

Facility managers may have vibration limits to protect sensitive equipment and activities.

Types of Vibration Damage

Cosmetic damage includes cracks in plaster, drywall, masonry walls, and corner joints of windows and doors.

Structural damage may develop from differential settlement, either from vibrations directly or from densification of foundation soil and loss of support.

Functional damage may include disruption of vibration-sensitive activities and damage to equipment at hospitals, clinics, laboratories, data centers, and chip fabrication centers.

Recommended Practices

Background data

Vibration monitoring programs should collect background vibration levels before the project begins. Trigger levels set lower than background vibrations can lead to unnecessary stop-work interruptions.

Photo surveys

Pre-construction photo surveys document existing defects in structures adjacent to the project. Such surveys may be required by local bulding codes and can shorten any litigation of damage claims.

Vibration Monitor Deployments

Bridge Repair

A GEO field engineer has installed a geophone on the pier along with a wireless portable vibration monitor.

Dynamic Compaction

A rugged wireless vibration monitor records vibrations from deep dynamic compaction.

Seawall Construction

This vibration monitor is recording sound levels and vibrations from pile driving operations.

Metro Station

A GEO field engineer has installed a geophone on the tunnel ceiling to monitor effects of demolition above.

Related Pages

Vibration Monitoring Equipment

What equipment is needed to monitoring construction vibrations? Can your project benefit from automated and wireless monitoring?

Instantel Micromate

Learn about instantel's best selling vibration monitor. Full specifications plus links to purchase or rent.

Rental Vibration Monitors

Request a quote for any of our vibration monitors, portable, fixed-location, manual or automated.